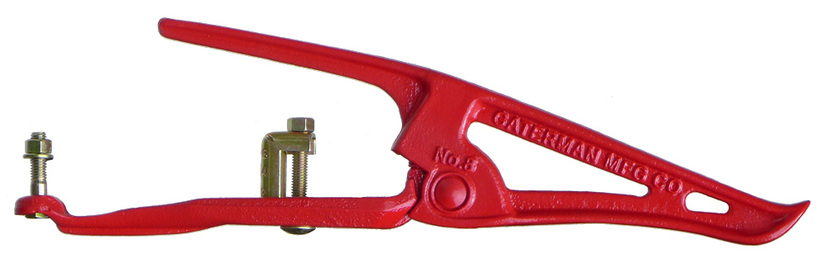

8B Crop Lifter

Our Most Versatile Crop Lifter

The 8B is a fully adjustable crop lifter (also known as pick up guard) used on all windrowers and combines with fixed, floating, or flexible cutterbars. The 8B crop lifter is constructed of high strength ductile iron for durability and long service life. Plated grade 8 fasteners are used for high strength and corrosion resistance. Note: The 8B crop lifter is used for 3" cut systems only. For 1½" cut systems, see the 4S crop lifter.

|

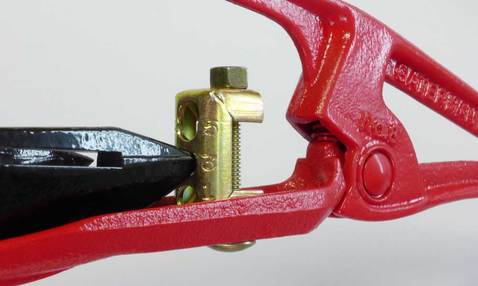

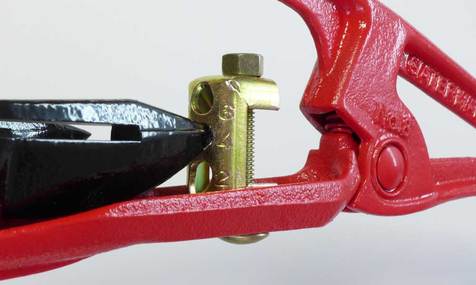

The height adjustment of the crop lifter tip is provided by the six-way adjustment block. Sickle guards with a variety of geometries can be accommodated by the various holes in the adjustment block. Different length sickle guards can also be accommodated by moving the block in it's mounting slot. The adjustment block is constructed of die formed steel and is yellow zinc plated for corrosion resistance.

|

This crop lifter is used extensively to harvest cereal crops (such as wheat, barley, oats, rye, and milo) on all windrowers, combines, floating and flexible cutterbars having sickle guards that stand level, such as Case, Cockshut, Deere, Ford Claas, (except Model 622), Gleaner, Hiniker, Hart Carter, Case IH 820-830 flexible bars, Lovebar, New Holland, New Idea, (except Model 717 flexible bar), Oliver, Versatile, White, and Year-A-Round. Used on combines with automatic header controls such as IH Flexible Bar, Gleaner, Massey Ferguson, New Holland, White (made after 1982), Roper Wright, M&W, Kelley, Noble, and Vesco header controls.

See 8B Application Guide for details.

See 8B Application Guide for details.

Note: For use on John Deere 600 series flex head grain platforms, the installation kit, INST-8BF is required.

Note: For use on Schumacher SCH Easy Cut II cutterbars, the installation kit, INST-8BS is required.

Note: For use on some Mac-Don 973, D50, D60, D65, FD70, FD75, CA25, FD1, D1, FM100, Case IH 2152, 2052, 2142, 2162,

2062, and New Holland 82C, 83C, 84C, 86C platforms equipped with poly wear plate (CNH# 87532221), the spacer kit,

SPK-CNH is required.

2062, and New Holland 82C, 83C, 84C, 86C platforms equipped with poly wear plate (CNH# 87532221), the spacer kit,

SPK-CNH is required.

|

|

|

Find a Dealer

or Buy Online |

RECOMMENDED CROP LIFTER SPACING

Sickle guard and cutterbar geometries can limit the available crop lifter spacing options. The following are starting recommendations that can be altered as the application requires.

|

Down Grain, Peas

|

Space Crop Lifters 6" to 9" Apart

|

|

Swath or Windrow

|

Space Crop Lifters 6" Apart

|

|

Rowed Beans and Milo

|

Space Crop Lifters 6" to 9" on each side of row. Closer spacing will reduce loss by raising crops uniformly.

|